Custom Sheepskin Garments Start to Finish

February 3, 2016

Behind the Scenes: A Custom Sheepskin Garment from Start to Finish

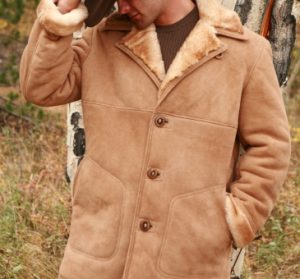

Sheepskin is one of the hottest trends this winter, and with the sheer number of people sporting shearling these days – be it real or faux – it may begin to seem like sheepskin garments are a dime a dozen. But what you probably don’t know is how much work and attention to detail actually goes into those authentic sheepskin slippers that you step into each morning, or that custom shearling coat that keeps you warm even on the most frigid winter days. At The Sheepherder, all of our sheepskin garments are handmade to order by a real person in an actual shop in Alma, Colorado, not a big-box retailer, and to appreciate the quality of the finished product, it helps to know the process.

Step 1: The skins we use for our sheepskin garments at The Sheepherder come from domestic sheep raised commercially for their meat in the western part of the United States, mostly in the Rocky Mountain region. The sheep, elk and deer that we use for our products are not an endangered species, and the hides are simply a valuable by-product of the animals.

Step 2: Before they come to us, the skins are sent to a tannery in the United States to be processed, an intricate system that involves 100 or so steps and takes a total of 21 days. The result is the soft, supple sheepskin that we use in our products, which naturally wicks away moisture from the body and keeps you cool even in the warmest weather.

Step 3: Once they are processed, the hides are ready to become one-of-a-kind sheepskin garments, which is where Diane Blessing comes in. Diane has been creating custom sheepskin apparel for more than 30 years, and her attention to detail is impeccable. When you place an order on The Sheepherder website or in the shop, your custom sheepskin garment is handmade by Diane herself, based on your specific measurements and style preferences.

Step 4: Unlike synthetic or imitation sheepskin, the genuine shearling we use at The Sheepherder is one continuous hide, which means the wool interior is a part of the skin itself, not a separate lining sewn or glued onto the hide. The softest and supplest skins we save for the sleeves and collars of our jackets, to ensure the highest level of comfort and flexibility.

Step 5: Once the hide is prepared by Diane and ready to become a jacket, a hat or a pair of slippers, the sheepskin garment is sewn together with tough nylon thread, and all of the seams are double-stitched for durability, so, with the right care, your shearling item will last for years to come.

Step 6: Finally, the buttons we use in our sheepskin coats and other garments are handmade from antlers that are naturally shed by deer and elk each year, which means that each set of buttons is truly one-of-a-kind and unique to your item.

Order Your Own Custom Sheepskin Garment Today

The next time you see a genuine sheepskin jacket, think about all the steps that go into making such an impressive product from start to finish – authentic hide, natural antler buttons and all – and you won’t be able to resist getting one for yourself. Place your order on The Sheepherder website today, and within weeks, you’ll have a custom shearling garment to call your own!